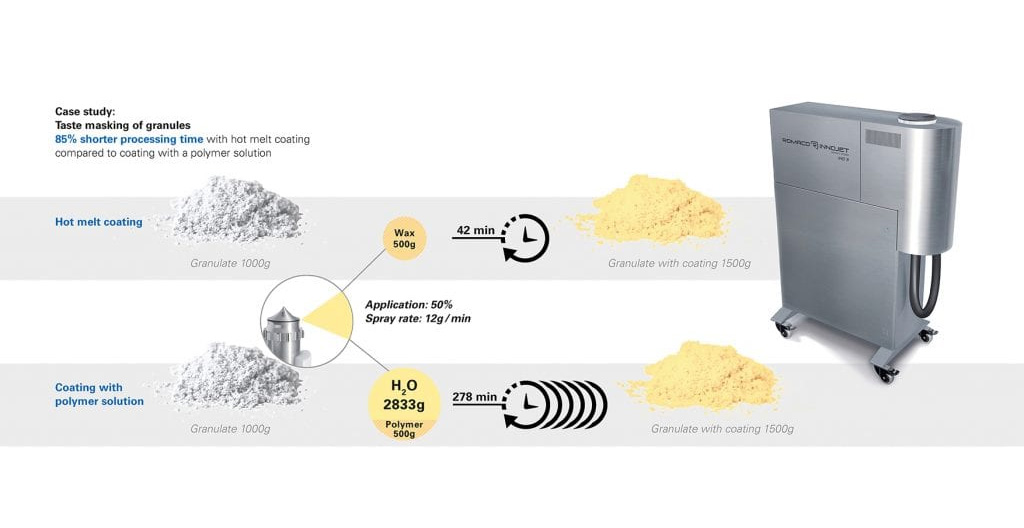

- Up to 85 percent shorter processing times

- Less spray is required because hot melt coatings are solvent-free

- One nozzle principle minimizes the spray loss

- Controlled product movement improves yield and product quality

- Unique filter design for long standing times

- Reduced cleaning times

- Fast spray solution preparation

… Hot Melt Coating … the smart way to handle your particles …

Sustainability

- 85% shorter processing times

- No solvent emissions

- Coating agents made from renewable plant-based raw materials

- No chemical additives

- No need to heat the air in order to dry the product

- Optimised energy efficiency

… Hot Melt … the green alternative to polymer coatings …

News

Nutraceuticals Hot Melt Coating Symposium at Romaco Innojet

Technical article that gives a deep insight into hot melt coating

Video

How to coat pellets with ready-to-use hot melt excipients

How to apply the coating with a single bottom spray nozzle

We look forward to your feedback!

Romaco Innojet GmbH

Daimlerstrasse 11

79585 Steinen

Germany

P +49 (0)7627 92377 25

E [email protected]

www.romaco.com

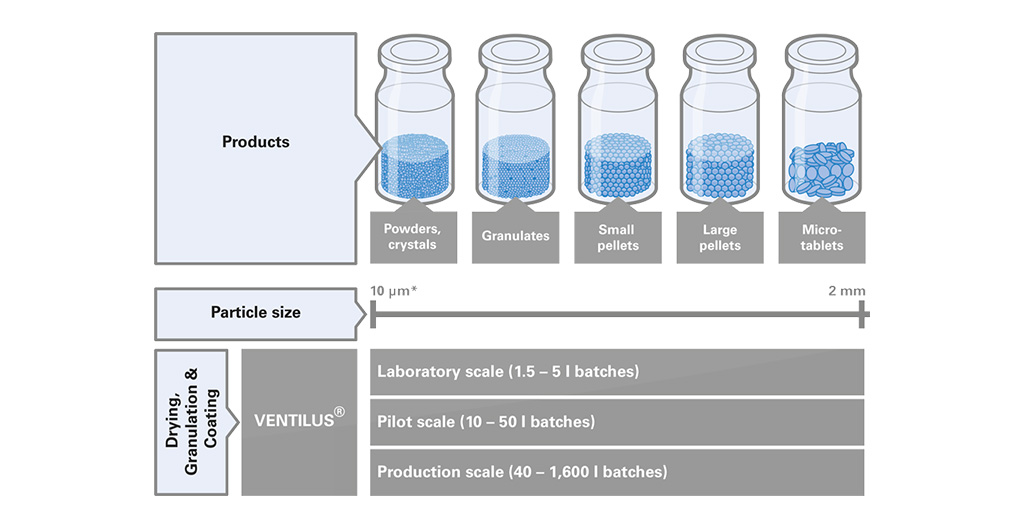

Romaco is a leading international supplier of processing and packaging equipment specialising in engineering technologies for pharmaceutical solids. The Romaco Group provides individual machines, lines and turnkey solutions for manufacturing and packing powders, granulates, pellets, tablets, capsules, syringes and medical devices. The company also serves the food and chemical industries. Through its various technologies, Romaco is committed to sustainable production and to systematically reducing CO2 emissions.

The Romaco Group has its headquarters in Karlsruhe (Germany) and is part of the Truking Group, a globally operating high-tech enterprise based in Changsha (China). Truking’s core competency is handling and filling pharmaceutical liquids.

Romaco operates from five European business sites with a broad portfolio comprised of seven established product brands. Noack and Siebler (Karlsruhe, Germany) supply blister, heat-sealing and rigid tube filling machines. Macofar (Bologna, Italy) markets technologies for filling sterile and non-sterile powders and liquids. Promatic (also Bologna, Italy) specializes in cartoners, track & trace systems and case packers. Kilian (Cologne, Germany) is a leading manufacturer of tablet presses. Innojet (Steinen, Germany) is in the business of granulating and coating fine solid particles. Tecpharm (Rubí, Spain) offers tablet coating technologies.

More than 800 highly skilled and committed Romaco employees are dedicated to the development of future product technologies and to the continuous implementation of internal improvement processes. Romaco’s multi-brand system solutions are sold worldwide through eight Sales & Service Centres and a dense network of local agent organisations. Over 12,000 installations delivered by Romaco are currently in use in more than 180 different countries.

For more information about the Romaco Group, visit www.romaco.com

Licensed images:

Title: GMP. Good Manufacturing Practice for medicinal products. Seal and imprint (© waldemarus / Adobe Stock)